|

Model |

WXCELL-180G |

|

Gas evolution (ml/g) |

185 |

|

Decomposition temperature ℃ |

170±5 |

|

Average particle size (μm) |

3-5 |

|

Chemical composition |

Azodicarbonamide |

|

Water content % |

≤0.1 |

|

Appearance |

Pale yellow powder with good dispersity |

Introduction

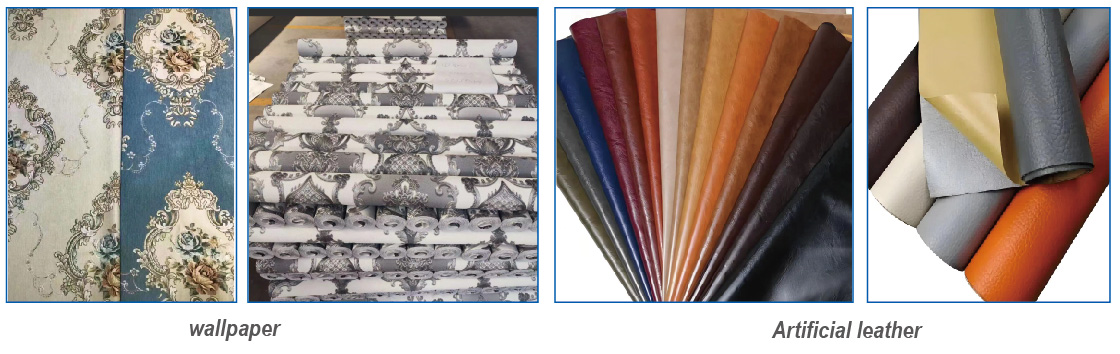

WXCELL AC foaming agent medium temperature series is crushed and sur-face modified by special process, so that the decomposition temperature is re-duced to between 170-180 degrees Celsius, which can meet the needs of some coating production processes, such as PVC coating artificial leather, wallpaper, floor mat extrusion foaming, etc. The product has uniform particle size distribution, low decomposition temperature, low energy consumption, fast decomposition rate, less decomposition residue, high whiteness, promotes plasticization, and makes the foamed products.

Advantage

Excellent dispersibility, no need to add any accelerator, suitable for PVC plasticizing temperature, improves plasticizing effect, the product has fine bubbles, good rebound, and particularly good whiteness. The amount of stabilizer added can be ap-propriately reduced, the amount of filler can be increased, and the cost can be reduced!

Technical data

|

Model |

WXCELL-180A |

WXCELL-180B |

WXCELL-180D |

WXCELL-180G |

|

Gas evolution (ml/g) |

200 |

190 |

180 |

185 |

|

Decomposition temperature℃ |

180±5 |

175±5 |

160±5 |

170±5 |

|

Average particle size (μm) |

6-8 |

5-6 |

6-8 |

3-5 |

|

Chemical composition |

Azodicarbonamide |

|||

|

Water content % |

≤0.1 |

|||

|

Appearance |

Pale yellow powder with good dispersity |

|||

Package and storage

Each package weighs 25 kg, according to customer needs medium temperature foaming agent series is non-toxic and odorless. It should be kept away from high temperature, direct sunlight, and avoid contact with acids .