|

Model |

WXCELL-1500 |

|

Gas evolution (ml/g) |

≥220 |

|

Decomposition temperature ℃ |

190-195 |

|

Average particle size (μm) |

12-15 |

|

Chemical composition |

Azodicarbonamide |

|

Water content % |

≤0.1 |

|

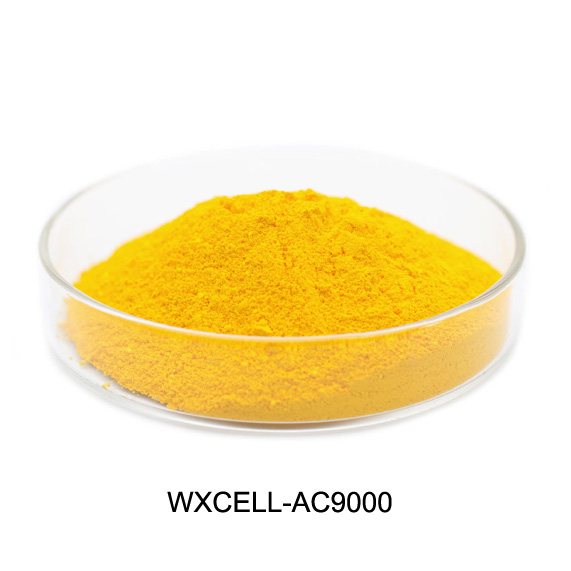

Appearance |

yellow powder with good dispersity |

Introduction

•LDPE chemical cross-linking extrusion continuous foaming process.

•LDPE electron radiation cross-linking extrusion continuous foaming process.

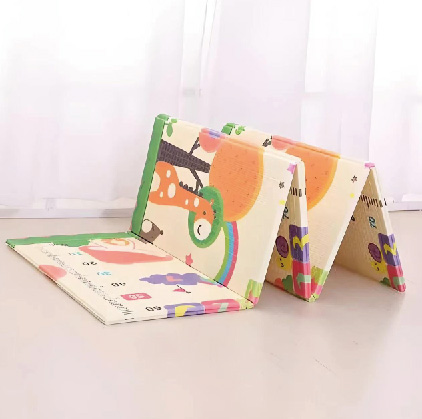

•Effectively used for thermal insulation materials, packaging materials, 3D wall stick-ers, climbing mats, car mats, foam sports equipment, etc.

This series of foaming agents are widely used in the production of PE foam products. PE foam is a chemically cross-linked polyethylene foam with low-density polyethylene resin and cross-linking agent and foaming agent. Through continuous foaming and high temperature, it is chemically stable, difficult to decompose, odorless and flexible.

Advantage

•Uniform pores

•Low product density

•Smooth product surface

Technical data

|

Model |

WXCELL-1500 |

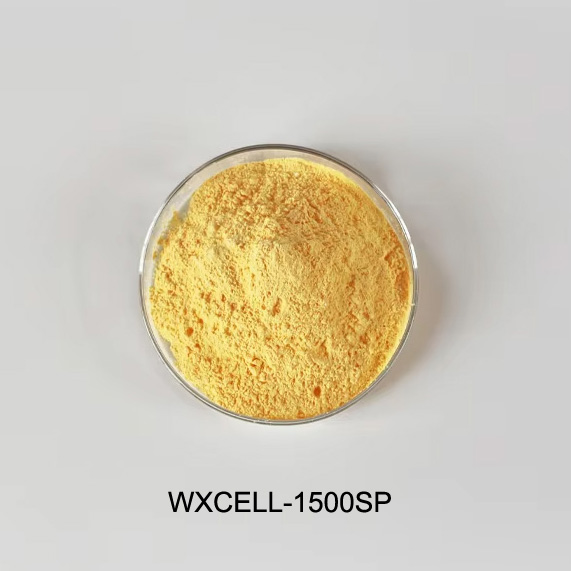

WXCELL-1500SP |

|

Gas evolution (ml/g) |

≥220 |

≥225 |

|

Decomposition temperature℃ |

190-195 |

200-205 |

|

Average particle size (μm) |

12-15 |

15-18 |

|

Chemical composition |

Azodicarbonamide |

|

|

Water content % |

≤0.1 |

|

|

Appearance |

yellow powder with good dispersity |

|

Package and storage

The weight of each package is 25 kg,

according to customer needs. WXCELL-R AC foaming agent series is non-toxic and

odorless. It should be kept away from high temperature, direct sunlight, and

avoid contact with acids and alkalis.